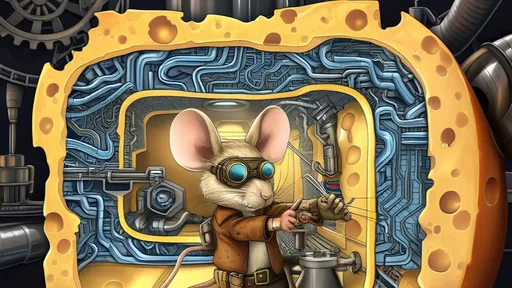

The world of cheese holds countless mysteries, but few are as fascinating as the intricate tunnels carved by microscopic engineers—molds. These tiny fungi, often viewed as unwanted guests in our refrigerators, are in fact master architects capable of transforming solid cheese into a labyrinth of delicate passages. Their work goes far beyond mere spoilage; it's a complex biological process that shapes texture, flavor, and even the cultural identity of certain cheeses.

The Silent Architects at Work

When we slice into a wheel of Swiss cheese and marvel at its characteristic holes, we're witnessing the aftermath of a microscopic excavation project. Propionibacterium freudenreichii, the primary bacterium responsible for these holes, produces carbon dioxide as it metabolizes lactic acid. The gas accumulates in pockets, creating those familiar round cavities. But in mold-ripened cheeses like Roquefort or Gorgonzola, the process is far more deliberate—a coordinated tunneling operation conducted by fungal networks.

Penicillium roqueforti, the blue-green mold celebrated in blue cheeses, doesn't simply grow on the surface. It sends hyphae—thread-like structures—deep into the cheese's matrix, secreting enzymes that break down proteins and lipids. As these digestive processes soften the cheese's structure, the hyphae physically push through, creating an interconnected highway system for nutrients and gases. What appears as random veining is actually a sophisticated transportation network designed to distribute nutrients throughout the fungal colony.

The Science Behind the Tunnels

Recent studies using micro-CT scanning have revealed the astonishing complexity of these fungal tunnel networks. Unlike the relatively uniform holes created by gas bubbles in Swiss cheese, mold tunnels follow branching, fractal-like patterns that maximize surface area while minimizing energy expenditure. The hyphae demonstrate what scientists call "thigmotropism"—the ability to sense and grow along physical structures—allowing them to navigate the cheese's protein matrix with remarkable efficiency.

Temperature and humidity play crucial roles in this underground construction. At cooler temperatures (around 8-10°C), mold growth slows, producing finer, more delicate tunnels. Warmer environments accelerate growth but create larger, less organized passages. Skilled cheesemakers manipulate these variables like conductors, guiding the mold to create specific textural qualities. The tunnels aren't just byproducts—they're carefully cultivated features that determine whether a blue cheese will be creamy or crumbly, mild or intensely pungent.

From Nuisance to Delicacy

Historically, cheese molds were likely accidental contaminants. Early cheesemakers storing their products in damp caves unknowingly provided ideal conditions for fungal growth. But somewhere along the way, someone tasted the veined cheese and discovered its complex, umami-rich flavors. This accidental discovery sparked an artisanal revolution—the intentional cultivation of mold as a flavor enhancer.

Modern blue cheese production carefully controls the mold inoculation process. Needles pierce the cheese wheels to create oxygen channels, encouraging interior mold growth. The tunnels formed by Penicillium serve multiple purposes: they allow oxygen to reach deep into the cheese (essential for mold metabolism), distribute flavorful breakdown products, and create the characteristic blue-green marbling that signals proper ripening. Far from being defects, these tunnels represent the cheese's living, evolving nature.

Engineering Lessons from Fungal Networks

The efficiency of mold tunnel networks hasn't gone unnoticed by scientists beyond the dairy world. Mycologists studying fungal growth patterns have found striking similarities between cheese mold networks and human-engineered transportation systems. Both prioritize efficient connectivity between nodes while minimizing redundant pathways. Some researchers are even applying these biological models to urban planning, using fungal growth algorithms to design more efficient road networks.

Materials scientists are particularly interested in how molds modify their environment. The enzymes secreted by cheese molds don't just create tunnels—they fundamentally alter the cheese's molecular structure, breaking down casein proteins into smaller peptides and free amino acids. This enzymatic engineering creates new textures and releases flavor compounds that wouldn't exist in unaged cheese. Understanding these processes could lead to bio-inspired methods for modifying food textures or creating novel materials.

The Future of Fungal Cheese Engineering

As biotechnology advances, cheesemakers are gaining unprecedented control over their microscopic collaborators. Genetic sequencing allows for the selection of specific mold strains that produce desirable flavors while minimizing bitter byproducts. Some researchers are experimenting with co-cultures—combining multiple mold species to create even more complex tunnel networks and flavor profiles.

Perhaps most intriguing are attempts to "train" molds through selective pressure, gradually guiding their evolution toward specific tunneling behaviors. Just as dogs were domesticated from wolves, cheese molds may be undergoing their own form of domestication—shaped by centuries of human intervention to create the perfect balance of structural integrity and flavor diffusion in our cheeses.

The next time you encounter a blue-veined cheese, take a moment to appreciate the invisible engineers that made it possible. Those delicate tunnels represent millions of microscopic decisions—a biological algorithm perfected over centuries, turning simple curds into one of humanity's most sophisticated fermented foods. In the hidden world of cheese caves and aging rooms, molds continue their quiet excavation work, proving that some of nature's best architects are too small to see.

By /Jul 7, 2025

By /Jul 7, 2025

By /Jul 7, 2025

By /Jul 7, 2025

By /Jul 7, 2025

By /Jul 7, 2025

By /Jul 7, 2025

By /Jul 7, 2025

By /Jul 7, 2025

By /Jul 7, 2025

By /Jul 7, 2025

By /Jul 7, 2025

By /Jul 7, 2025

By /Jul 7, 2025

By /Jul 7, 2025

By /Jul 7, 2025

By /Jul 7, 2025

By /Jul 7, 2025